| I&T Solution |

Highrise spine inspection robot

(REF : S-1180)

|

| Trial Project |

|

| Solution Feature |

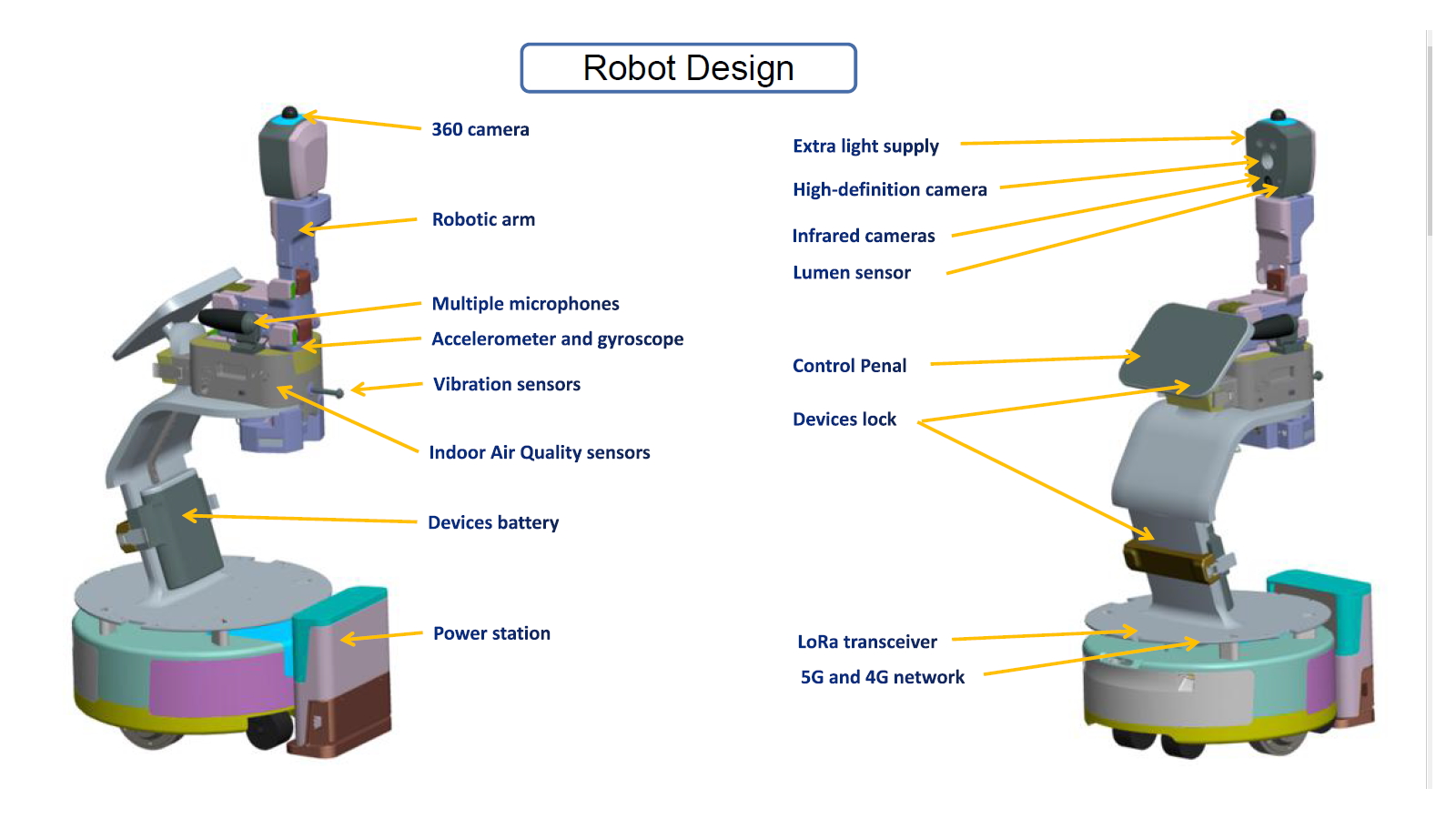

- Vibration sensors installed on the robot will collect data to be analyzed by the backend AI and will be able to detect and predict problems in the elevator. The vibration sensor will also detect the leveling discrepancy between the elevator and each floor's ground.

- Accelerometer and gyroscope will be used to analyze the speed, stability, and jerk of the elevator. The RoboLift Module will provide the floor number to correlate with the data obtained by the accelerometer and gyroscope. The analyzed data will ensure the elevator stability.

- Multiple microphones will be installed to track the environmental noises from low to high pitch. The detected sound waves are fed into a Machine Learning AI, and find out sound patterns that could predict faulty incidents in the future.

- A Robotic arm carrying 360 cameras and infrared cameras will be installed to check for water leakage, building interior flaws and patrol the premises. A special vision AI will be able to analyze the 360 images.

- Lumen, IAQ and other chemical sensors will be added to the mobile robot. The data obtained will be broadcasted live to the RDCC BIM model to ensure a safe and healthy environment for human beings.

|

| Trial Application and Expected Outcome |

- The lift module will be installed into one of the elevators in EMSD headquarters. The module will be connected to all 6 robots. Autonomous traveling from floor to floor will be tested at night when no one is using the elevators to ensure full functionality of the lift module.

- The Spine Inspection Robots will install the motherboard with all the sensors and start patrolling the entire EMSD at night. We expect the robots to start collecting raw data with the sensors in every floor, and the data is fed into our backend servers.

- Machine learning will continuously run in the backend. The robots will feed as much videos, sound waves, vibration data and IAQ info back to the cloud servers. We will create a pipeline for data transfer to limit the throughput to keep the lowest server cost, which is essential for commercialization.

- The final step to train the predictive maintenance AI analytic is to compare human inspection results with robotics inspection results. Our engineers will try to manually identify flaws in the elevators and the buildings and teach the AI system about them.

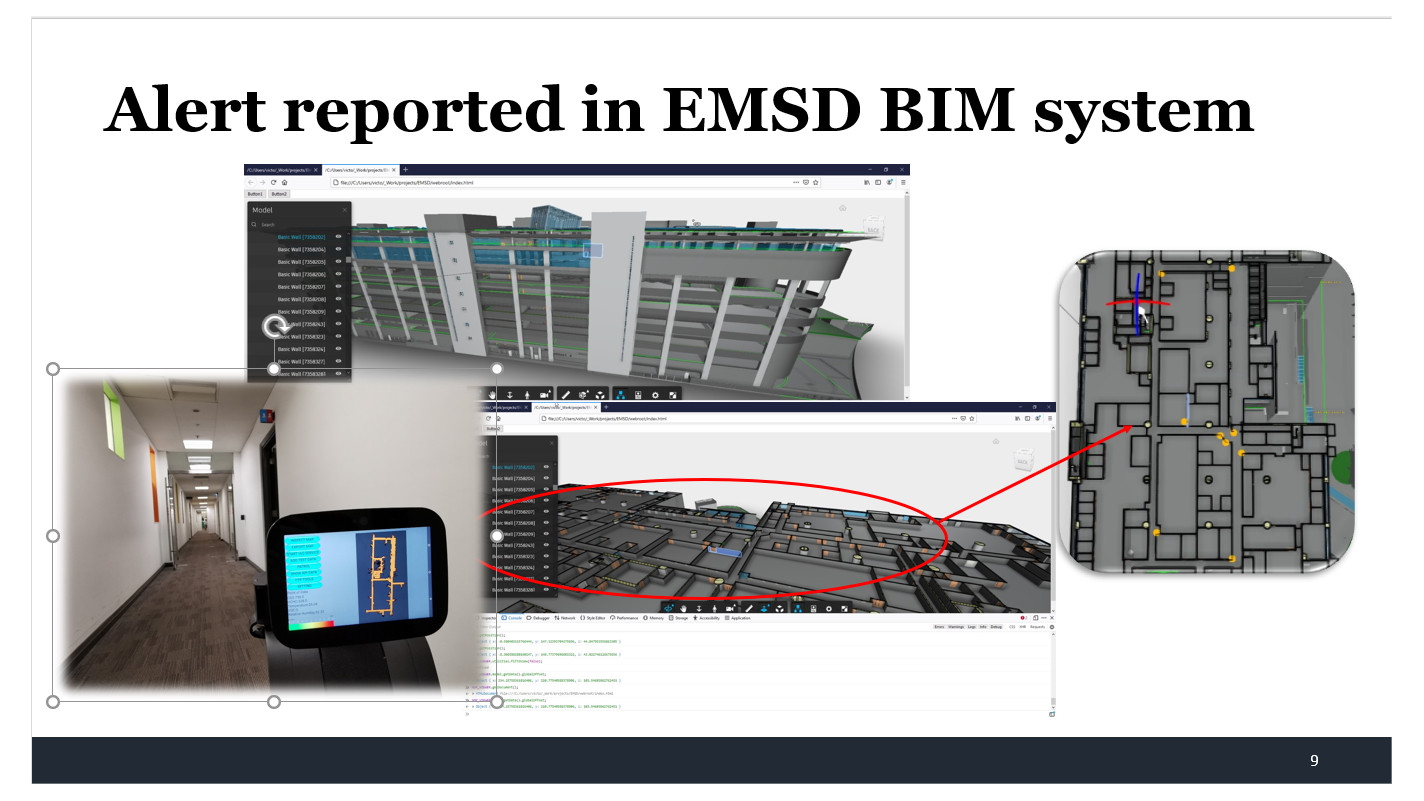

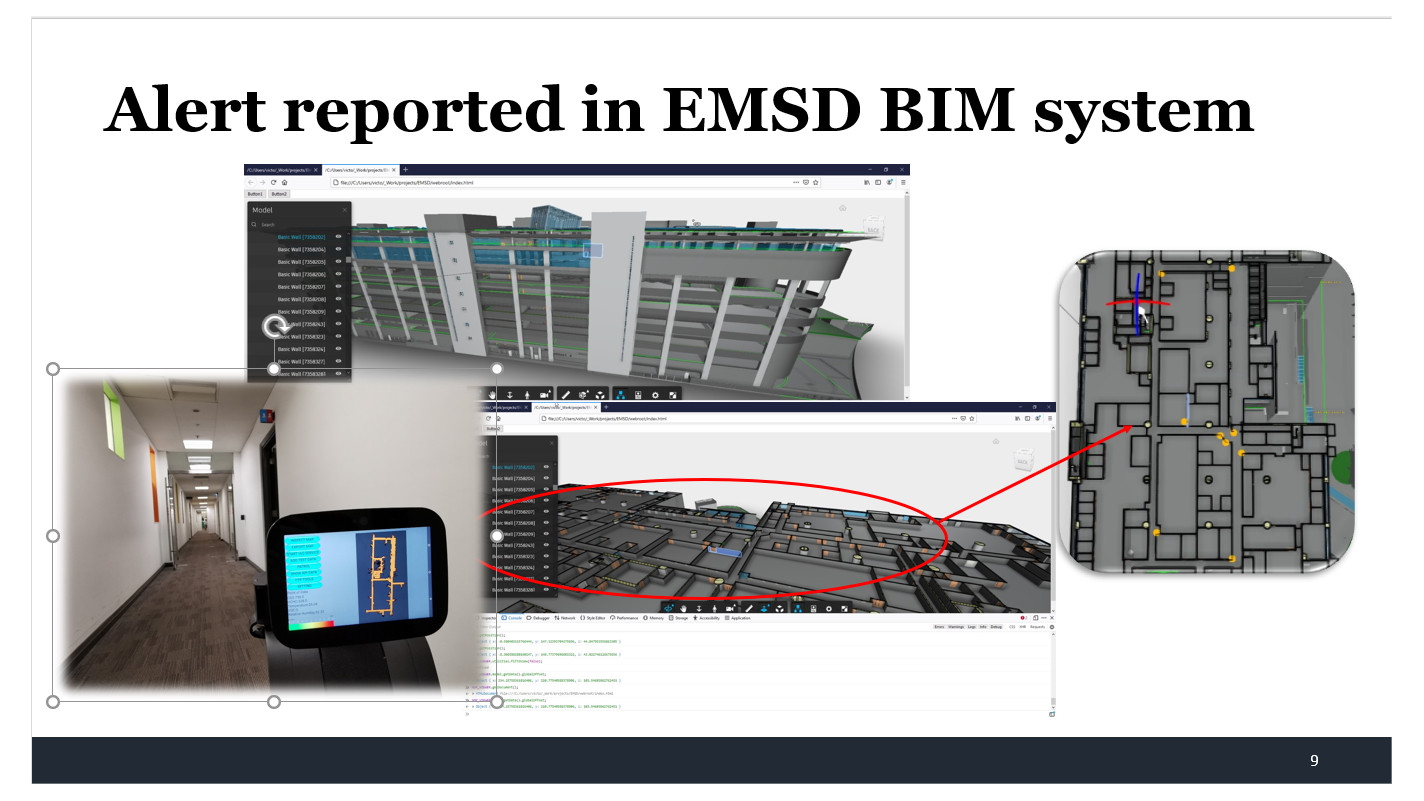

- The analytical results from the servers will be fed back to the RDCC BIM model. Some instant results from the Spine Inspection Robots will also be broadcasted. The BIM model display will be redesigned to faciliate a real-time view of all the robots in the entire building.

|

| Additional Solution Information |

Proposal for Project Backbone implementation.docx

|

| Info on I&T Solution Provider |

| Solution Provider | : | Robocore Technology Ltd. |

| Address | : | Unit 211, Building 19W, Hong Kong Science Park |

| Contact Person | : | LIM, Long Hei Roy |

|

Position | : | CEO

|

|

Tel | : |

27565118

|

|

Email | : |

roy@robocore.ai

|

|

Webpage | : |

robocore.ai

|

|