| I&T Solution |

Cremation Process Automation System

(REF : S-0236)

|

| Matched I&T Wish |

|

| Trial Project |

|

| Solution Feature |

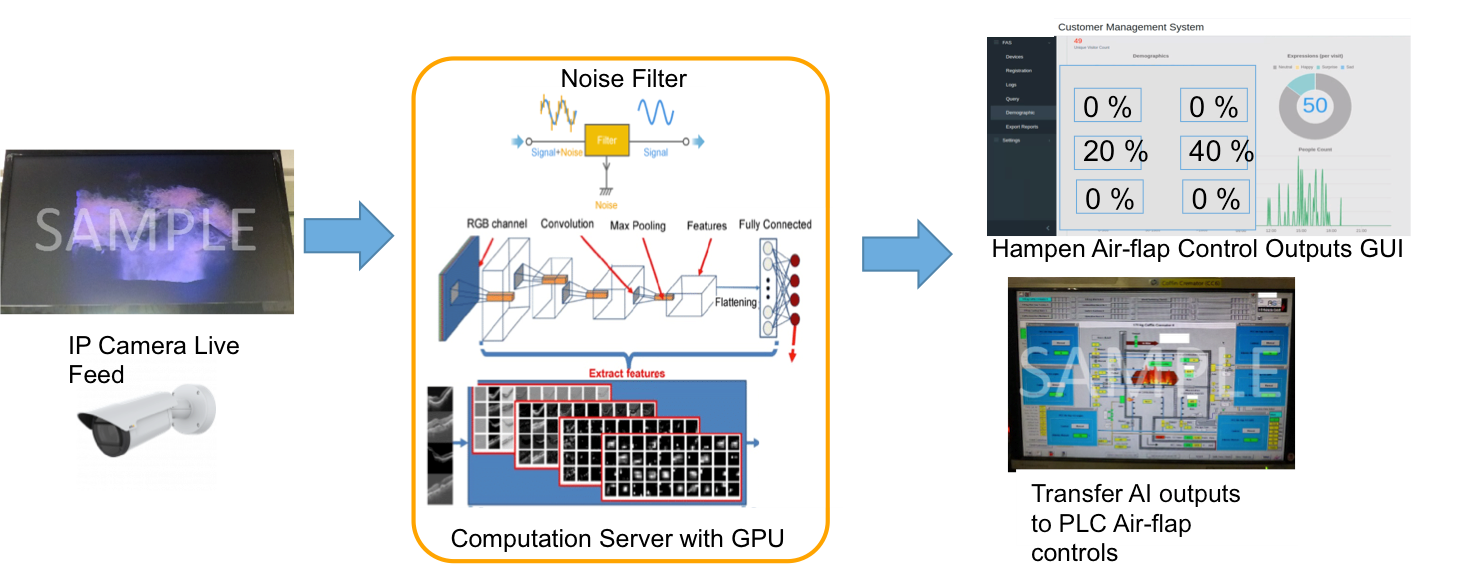

- Cremation Automation System analyses real time cremation images and automatically control air-flaps to fully automate the cremation PLC control process. Optimization goal is to reduce the overall cremation time and pollution/emission.

- The system consists of: 1. Input IP cameras, which capture input images through live streaming. 2. Computation GPU Server, which runs a Convolution Neural Network that will classify the camera images to determine the state of the cremation process and responses. 3. Air-flap Control Output GUI to control PLC.

- The first stage of the project will involve data collections and CNN model design and development. Image and coffin content data will be collected from all 6 chambers for training (to avoid over-fitting to certain chamber’s data set)

- The second stage will involve model training and trial runs. Initially trained model will be used to provide AI generated air-flap control outputs and be imported into PLC for automated controls. Data will be collected through trial runs and results will be collected for further optimization.

- The final stage involves analyzing the initial model’s results and collecting additional training samples for further optimization on cremation time and emission. We will correlate the results with coffin/body weights, type, sizes, preservative level to identify trends and optimization strategy.

|

| Trial Application and Expected Outcome |

- The trial stage will involve model training and trial runs. Initially trained model will be used to provide AI generated air-flap control outputs to be imported into PLC for automated controls. Data will be collected through trial runs and results will be collected for further optimization.

- The deliverables will include CNN model, server hardware, Tomcat Application Software server for video stream decode, classification/response generation, CMS for stream/processing thread monitoring and user manual and training/troubleshoot documents

|

| Info on I&T Solution Provider |

| Solution Provider | : | Hampen Technology Corporation Limited |

| Address | : | 5B, Mackenny Centre, 660 Castle Peak Road, Cheung Sha Wan, Kowloon. |

| Contact Person | : | Felix Chow |

|

Position | : | CEO

|

|

Tel | : |

9186 3684

|

|

Email | : |

fchow@hampentech.com

|

|

Webpage | : |

www.hampentech.com

|

|