Fibre Optic Sensing System for Chilled Water Pipe Leakage Detection (REF:C-0041)

E&M InnoPortal Trial Project Ref. No.:

Overview

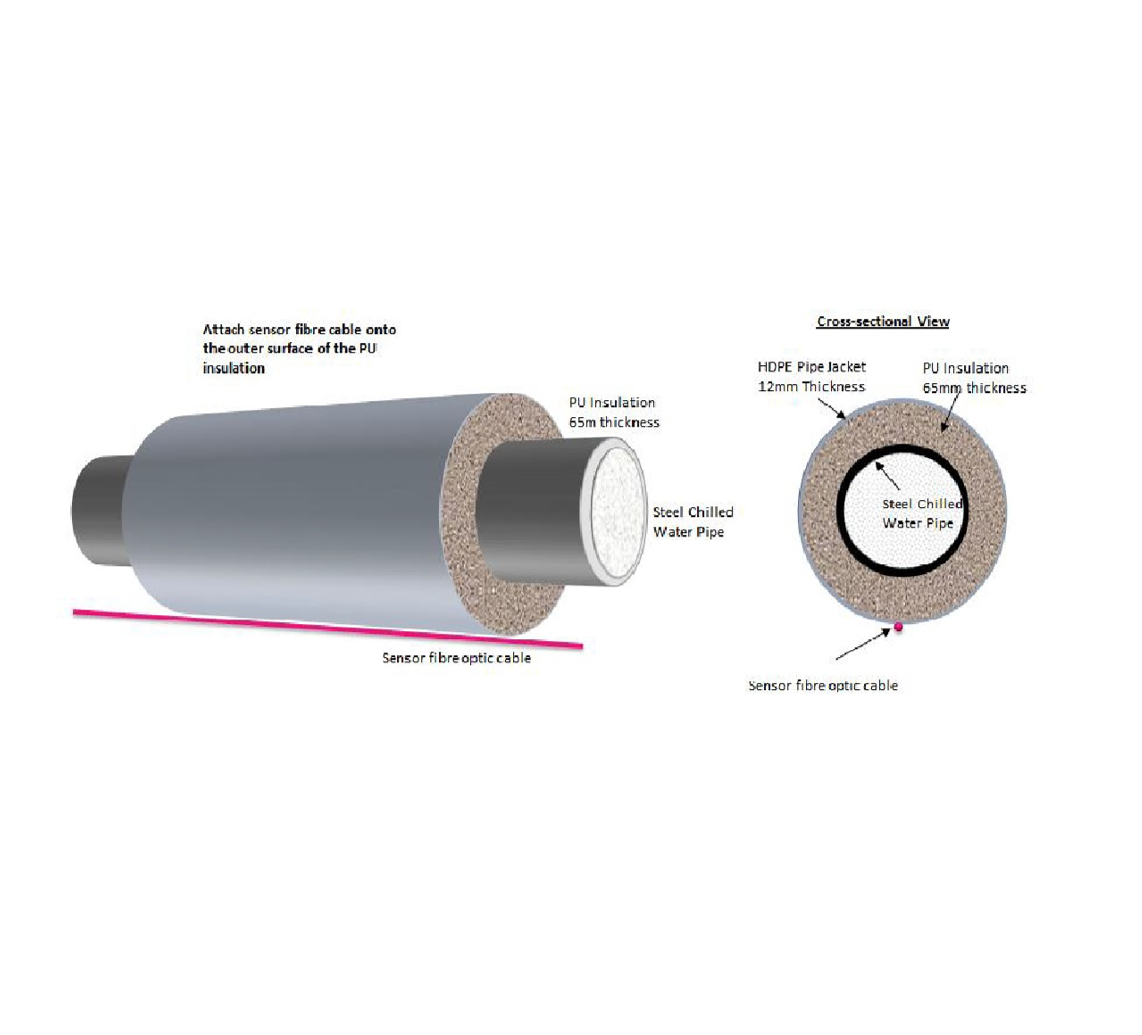

A leakage detection system using fibre optic sensing system is designed and deployed to detect leakages of pipes in a real time manner. The system incorporates a fibre optic distributed temperature sensing system to detect leakage of chilled water pipes and return water pipes.

| Problem Addressed | Very often, several hundred metres of pipes are necessary to convey cold water from the water chiller to the heat exchangers and to transport the warm water back to the chilled water pumps. These pipes at times experience bursting or leakage due to structural issues such as corrosion, damaged joints, loose connectors, vibration and settlement or water pressure issues like clogged pipes and excessive pressure. Timely detection is essential to maintain operations. |

|---|---|

| Innovation | The system makes use of fibre optic cables as the continuous temperature sensing media. A Main Control Unit (MCU) emits laser pulses into the cables. As the laser pulses travel along the cables, light is reflected at locations where total internal reflection occurs at every 400 mm space intervals. The reflected light, called back scattered light, is then collected by the MCU. The temperature along the cables changes the wavelength of the back scattered light compared with the emitted laser light. The detection methodology continuously monitors the temperatures along the external surface of the chilled water pipes. When leak occurs, the chilled water will come into contact with the cables. The ambient temperature, namely the air temperature of the environment, around the installed pipes, serves as reference. By comparing the temperature readings of chilled water pipes and return water pipes, any leak can be identified. Big data analytics techniques are applied to historical operations profile, real-time comparison and location analysis. |

| Key Benefits |

|

| Project Reference | Tsuen Wan Government Office Building |