| I&T Solution |

Inspection robot for drainage assets

(REF: S-0823) |

| Trial Project |

|

| Solution Feature |

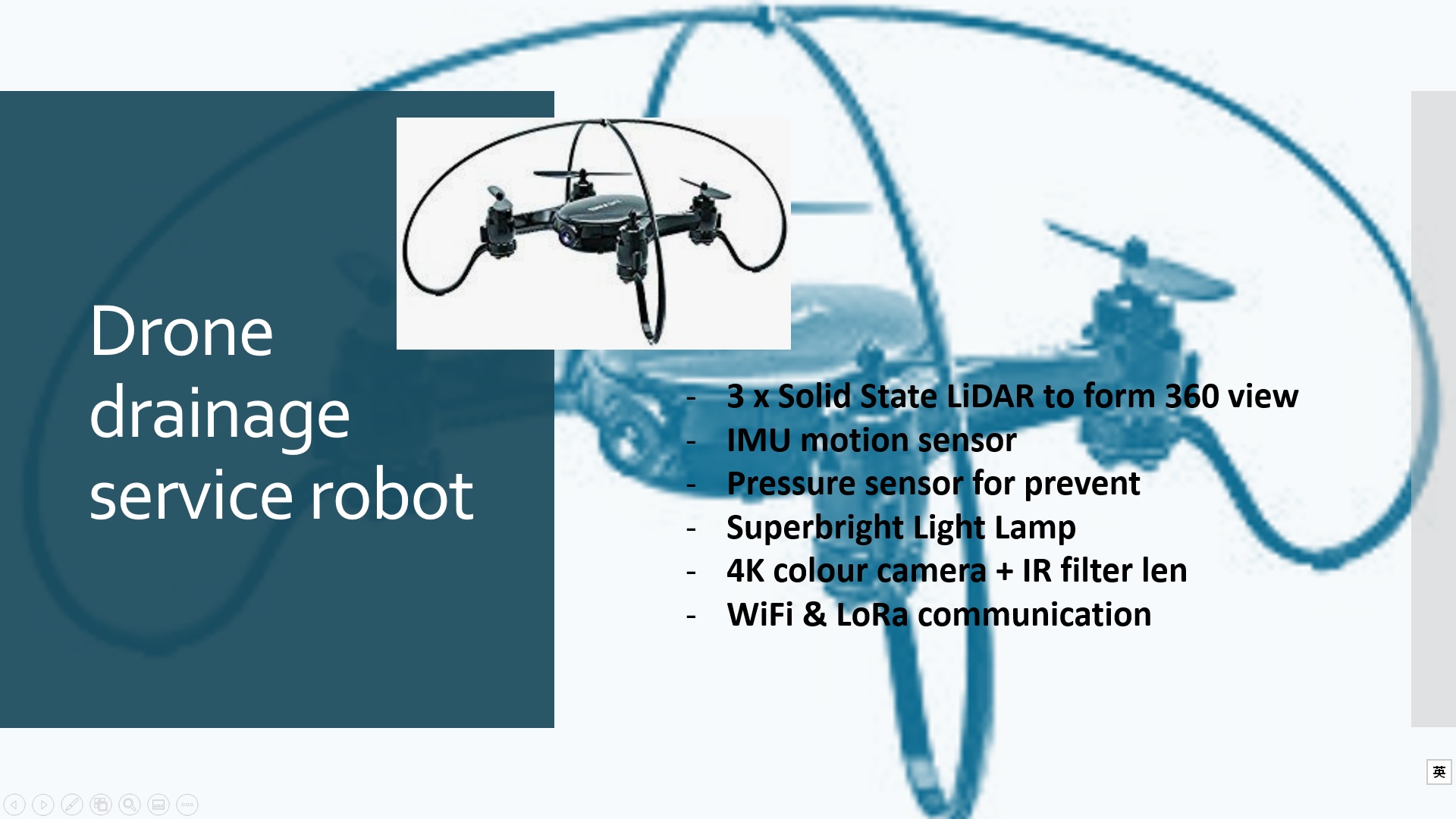

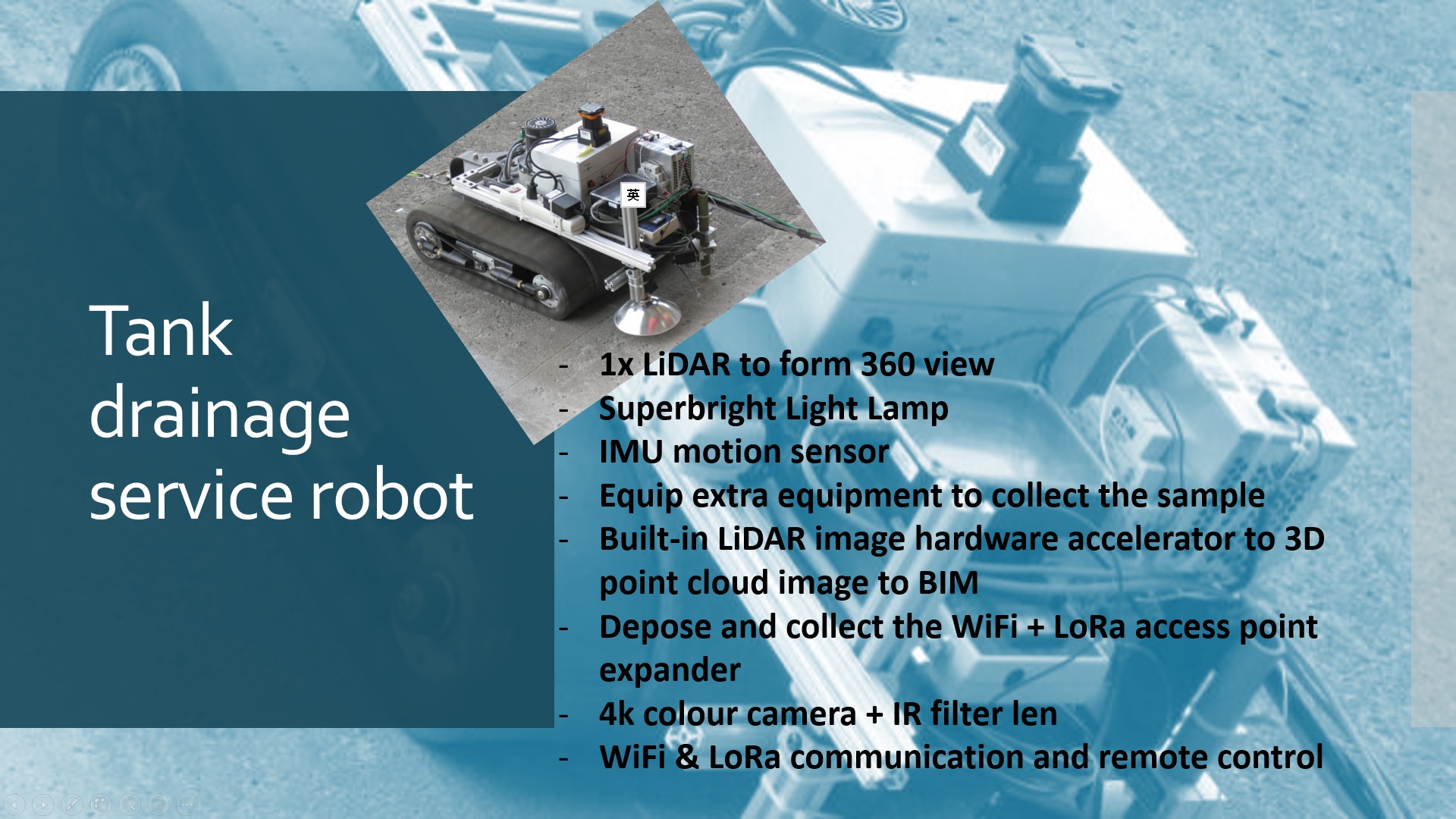

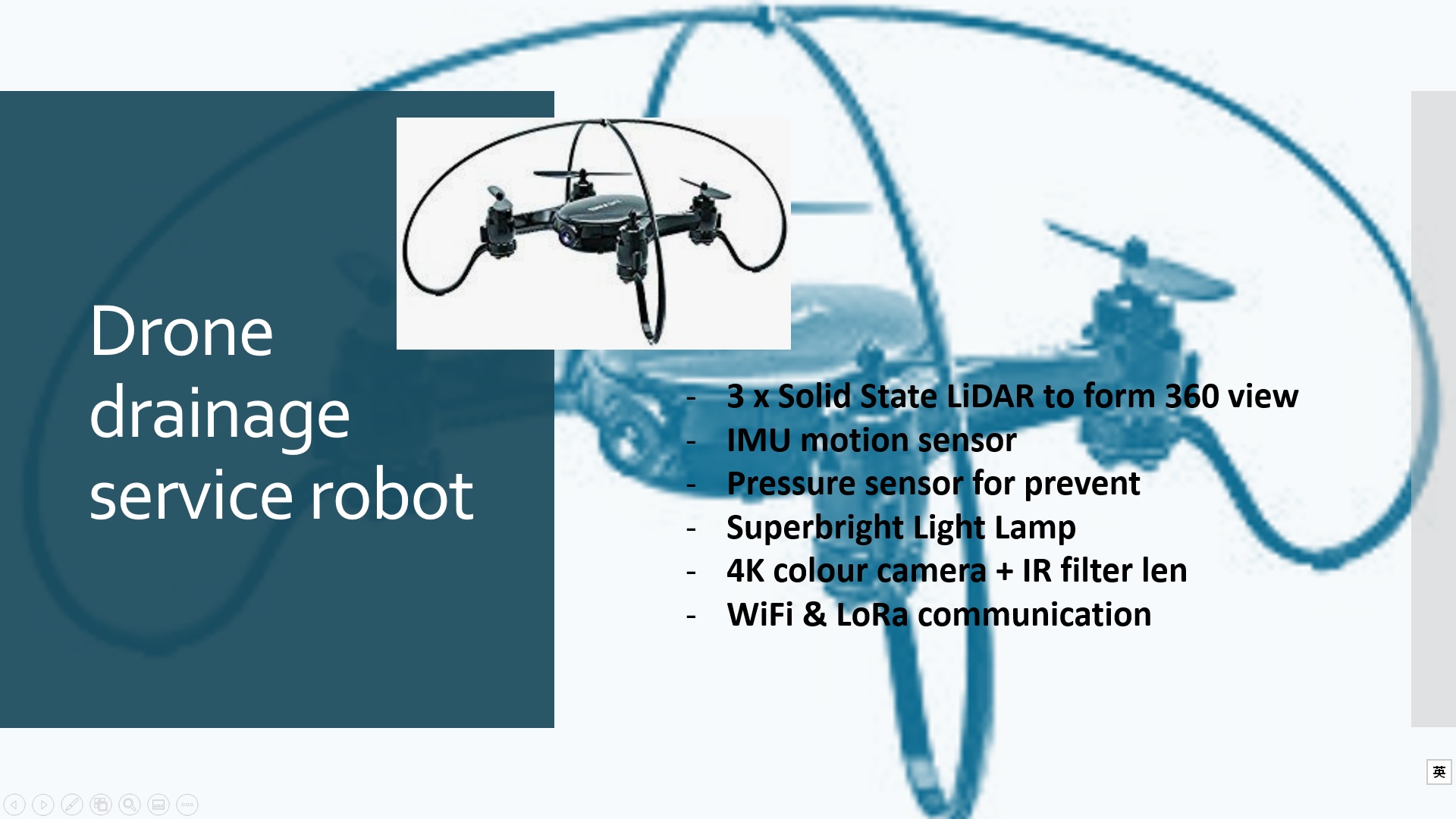

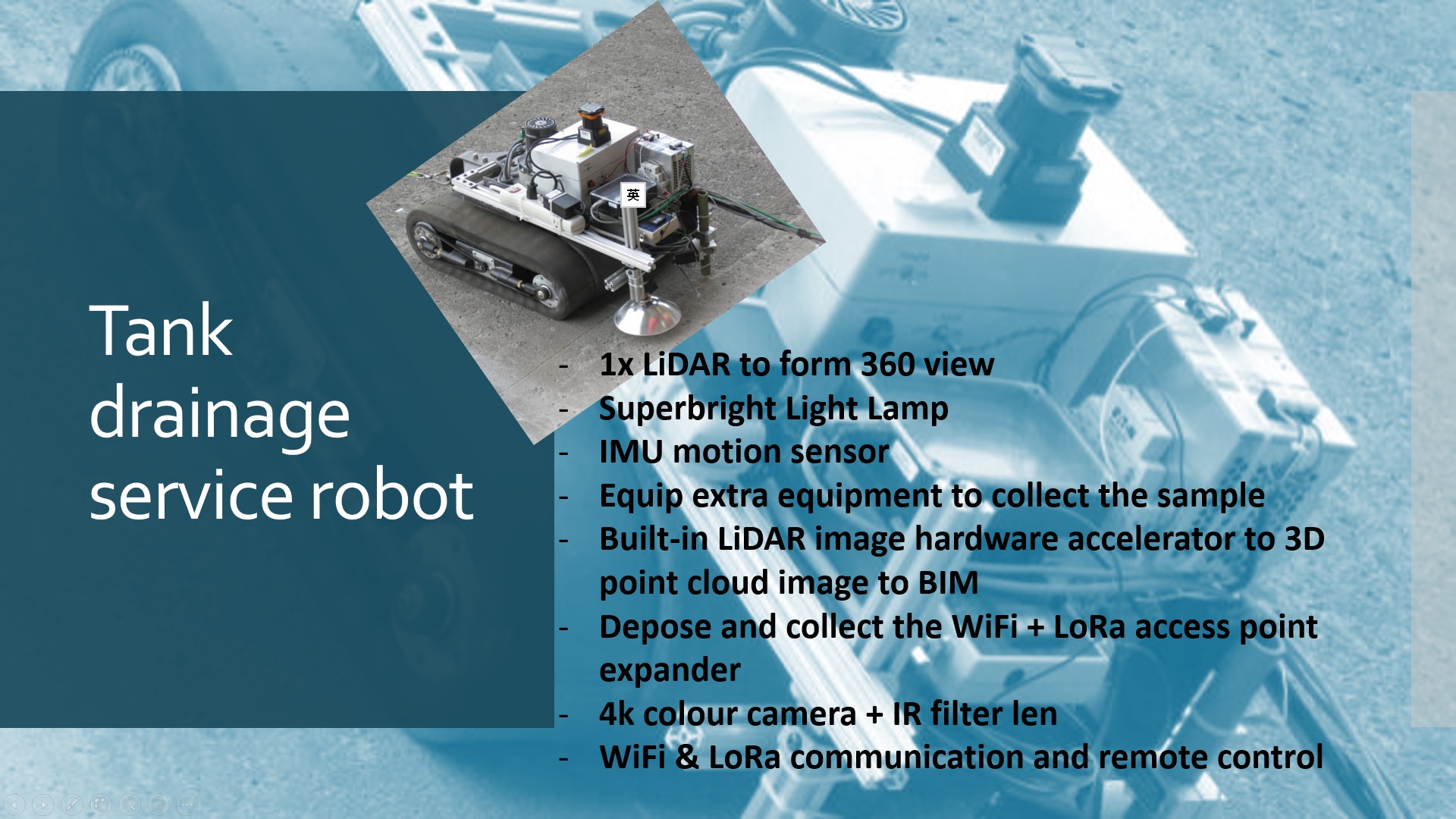

- Sampling and inspections can be done by the drone or a tank, both of which can be combined to become a single unit. These robots can be remotely controlled by the operator above the ground, free from occupational hazards.

- The drone is sitting on top of the tank when not in use. The tank can carry the drone to cover most of the sampling site, and only activate the drone where needed (e.g. surveying and sampling areas involving vertical pipes). The longevity of battery operation can be therefore preserved.

- The tank and the drone each have a solid-state LiDAR, 4K IR/thermal cameras, and lighting source for the operator to see in colour. Tthe robots can operate in complete darkness. The LiDAR would further generate point cloud model of the surroundings and will be outputted as a 3D BIM model.

- Connectivity to the IoT devices can be provided by a WiFi + LoRaWAN module being descending into the inspection site, connected to 5G/4G network from above the ground. WiFi router will be installed on the tank, carries detachable range extenders that can be dropped and recollected to optimise operational range.

- Water sampling can be done via syringes being stored in a revolver compartment. The operator will signal to the robotic arm to engage an empty syringe, control the robotic arm to collect samples. Collecting samples via the drone can be done via a descending bucket attached to the motor reel.

|

| Trial Application and Expected Outcome |

- A WiFi + LoRaWan setup (with corresponding range extender) will be descended inside the underground area to ensure the important inspection assets are always connected and in full control.

- The equipment can work in an insanitary environment surrounded by hazardous gas (e.g. CO, H2S, CH4). The inspector can identify the conditions of corrosion, mechanical wear, abnormal flow, cracks and leaks without entering the high-risk area himself. The unmanned approach substantially improves the occupational health and safety of workers.

- The combination of a drone sitting on top of a separately controllable tank would allow the inspector to decide on the sampling approach in yielding the best result, at the same time the short-lived battery life on the drone can be preserved until needed.

- The combination approach of the 4k IR/Thermal camera and LiDAR sensors not only allows the inspector to identify visual cues, but also being able to “see” clearly with laser and radar images in total darkness, including the minor cracks.

- The locally developed AI-based LiDAR hardware accelerator will not only enhance the quality of the point cloud output, but it can also further construct a scaled BIM model where your department may make use of as a 3D model.

|

| Info on I&T Solution Provider |

| Solution Provider | : | Tech Hill Limited | | Address | : | Unit 1059, 10/F., Incubation Centre, Building 19W, No.19 Science Park West Avenue, Hong Kong Science Park, Shatin, N.T., Hong Kong | | Contact Person | : | MOK Wai Pong |

| Position | : | Chief Technology Officer | | Tel | : | 96337378 | | Email | : |

wpmok@techhillltd.com | | Webpage | : | https://www.techhillltd.com |

|