| I&T Solution |

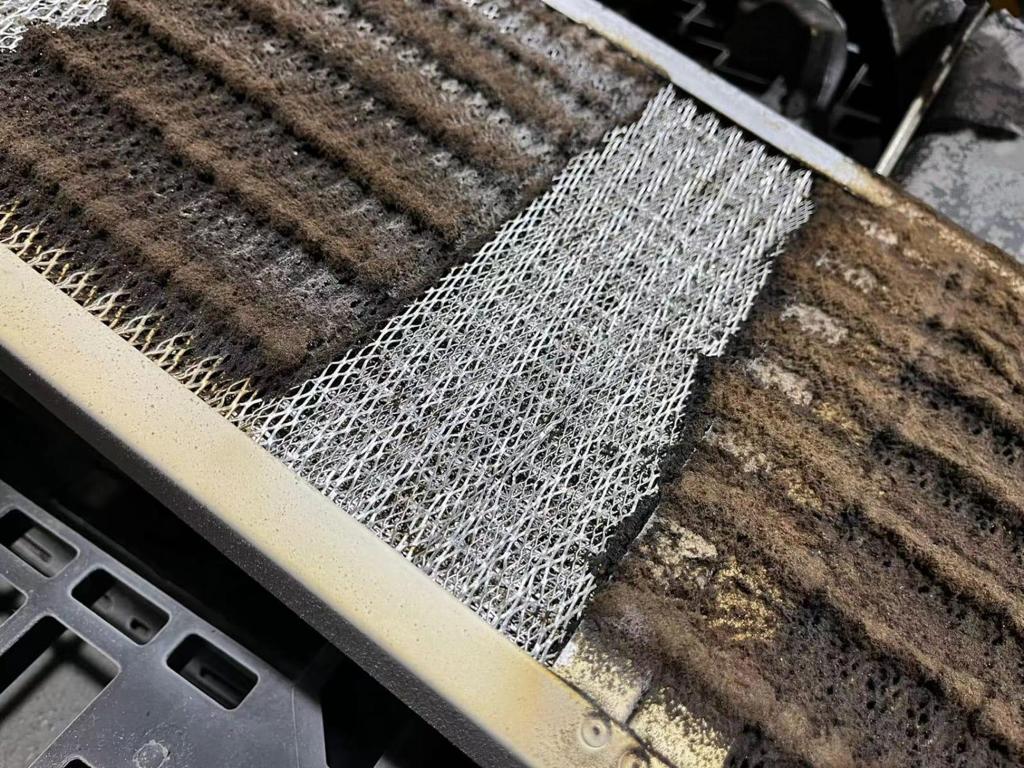

Effective Grease Filter Cleaning Solution

(REF: S-1273) |

| Trial Project |

|

| Solution Feature |

- Disassembly of filters not required- Surface can be cleaned without disassembly of filters (even if hot). No electric hazard as surface remains dry unlike solvent based cleaning.

- No secondary waste- As dry ice sublimates together with contaminant, there is no secondary waste streams after use.

- Non-abrasive- The surface of the filter will not be eroded over time as this form of cleaning is non-abrasive (unlike the use strong solution and chemicals to remove grease stains).

- Increased portability- Unlike ultrasonic machines which require relatively large area of space, the dry ice blasting machine is portable and can be taken to each kitchen to conduct thorough cleaning works.

|

| Trial Application and Expected Outcome |

- Efficient removal of stubborn grease- The high pressure combined with thermal shock from dry ice blasting can remove stubborn grease from filters more efficiently. DIB can also reach tight spaces when directed to such areas.

- Environmentally friendly- No water or chemical is used during the cleaning process resulting to toxic free & low risk of contamination. Dry ice cleaning has been approved by USDA, FDA and EPA guidelines

- Less labour intensive- Do not require extensive scrubbing for removal of contaminant or wipe-down after complete. No dismantling required unless thorough cleaning including exhaust ducts are needed.

|

| Additional Solution Information |

Proposal for Grease Filter Cleaning v2.pdf

|

| Info on I&T Solution Provider |

|