| I&T Solution |

Smart Detection of Railway Point Machines

(REF: S-1482) |

| Trial Project |

|

| Solution Feature |

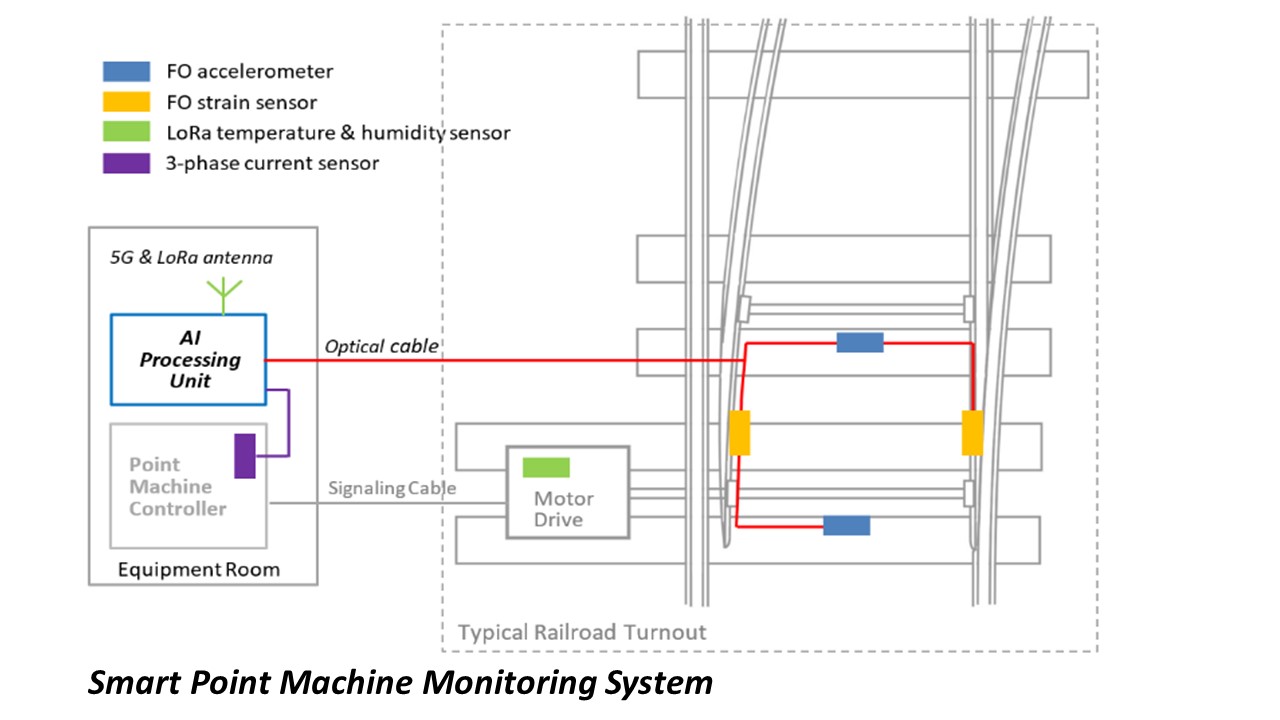

- The sensory part of the smart point machine monitoring system composes of sensors based on different sensing technologies. By leveraging the strengths of multiple sensing technologies and analyzing the combined data in a single system, the chances of detecting fault signatures could significantly be increased.

- Co-development of innovative technology by team formed by government, university and industry. In this government supported project, the small size and low power consumption fibre-optics FBG interrogator will be co-developed by PolyU academics. They will also support this project by providing domain expertise in railway industry.

- The proposed smart AI point machine monitoring system acquires both static and dynamic behaviors of point machine by using multiple sensing technologies, this type of comprehensive monitoring platform currently is not available in the market.

- The smart point machine monitoring system adopts artificial intelligence algorithms to perform essential data analytics that enable rapid, real-time analysis and response with greater reliability. Availability of prognostic tools developed by this monitoring system enable current maintenance strategy to be migrated from routine-, condition-based to predictive and proactive-based.

- System upgradability – by considering versatility during project implementation, the hardware, software as well as AI models developed in this project could be applied to different types of point machines. In addition, multiple monitoring systems could be integrated into the same platform for easier management.

|

| Trial Application and Expected Outcome |

- An innovative smart point machine condition monitoring system comprises multiple sensors, 5G enabled data processing unit embedded with AI analytics algorithms will be delivered. The system will be tested at a point machine in train depot and further installed on 5 designated point machines at mainlines.

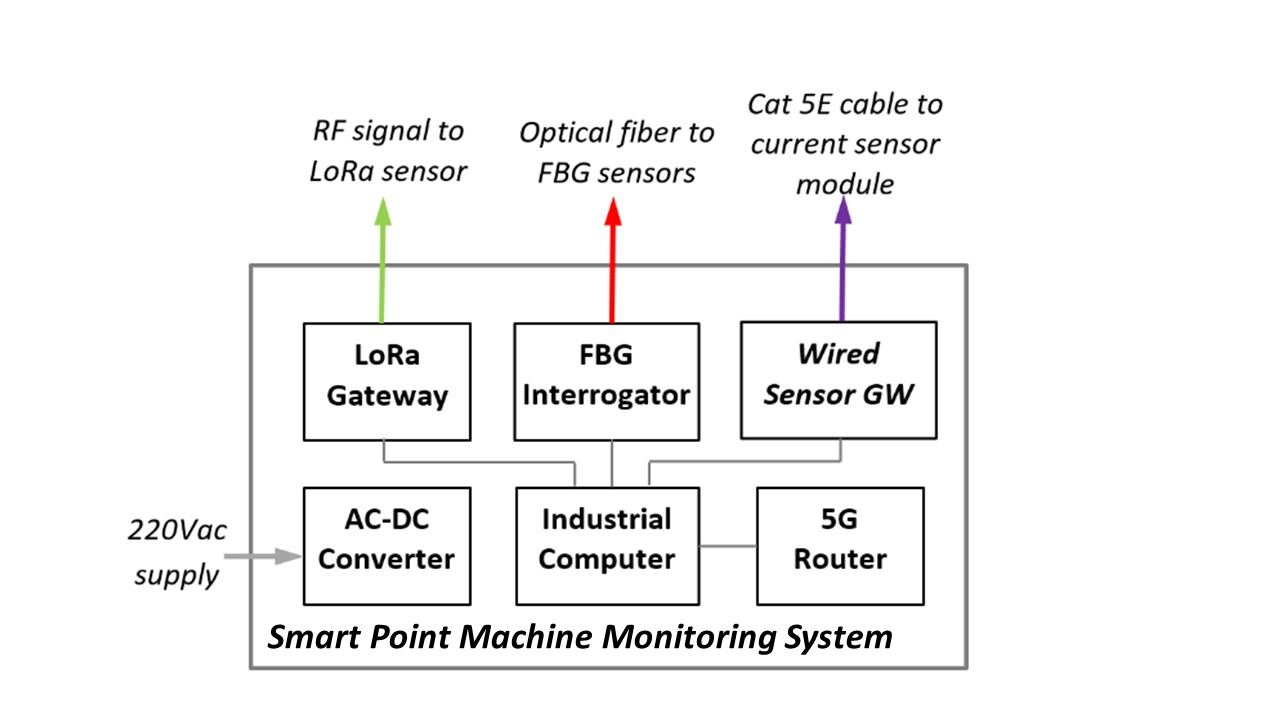

- Fibre-optics vibration and strain sensors, LoRa based temperature and humidity sensor and high sampling 3-phase current sensor for measuring operational characteristics of point machine will be developed in this project.

- A 5G enabled, customized data processing unit for sensor interrogation, data processing and warning signal generation and remote reporting via 5G mobile network will be delivered in this project.

- Artificial intelligence and machine learning decision algorithms will be developed after the data collection and fault simulation testing period. These algorithms will be installed into the data processing unit to analysis the new data so as determine the real-time operation condition of the point machine being monitored.

- Web-based graphical user interface will be developed at the final stage of the project. The interface should able to show the real-time operation condition of point machine and provide prognostic tool showing the information based on statistics and findings from the passed data for early defects identification.

|

| Info on I&T Solution Provider |

| Solution Provider | : | Avaron Technologies Company Limited | | Address | : | Unit 332, 3/F, Building 19W, No. 19 Science Park West Avenue, Hong Kong Science Park, Pak Shek Kok, N.T., Hong Kong | | Contact Person | : | Cheng Kin Wai |

| Position | : | Project Manager | | Tel | : | 95141091 | | Email | : |

eric.cheng@avarontechs.com | | Webpage | : | https://avarontechs.com/ |

|