| I&T Solution |

Remote Condition Monitoring & Smart Detection For Railway Point Machines

(REF: S-1485) |

| Trial Project |

|

| Solution Feature |

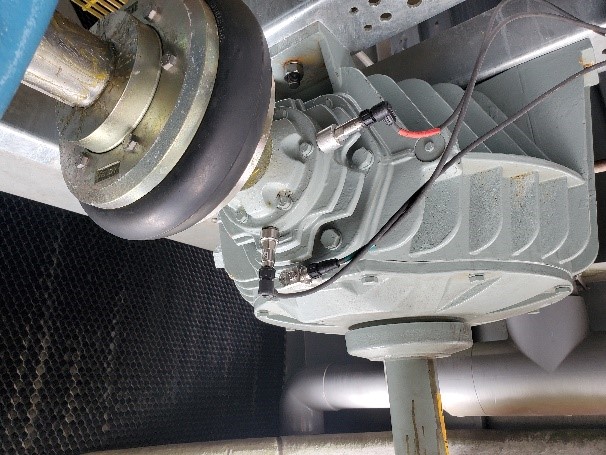

- Remote and wired Condition monitoring on the driving motor & gear set

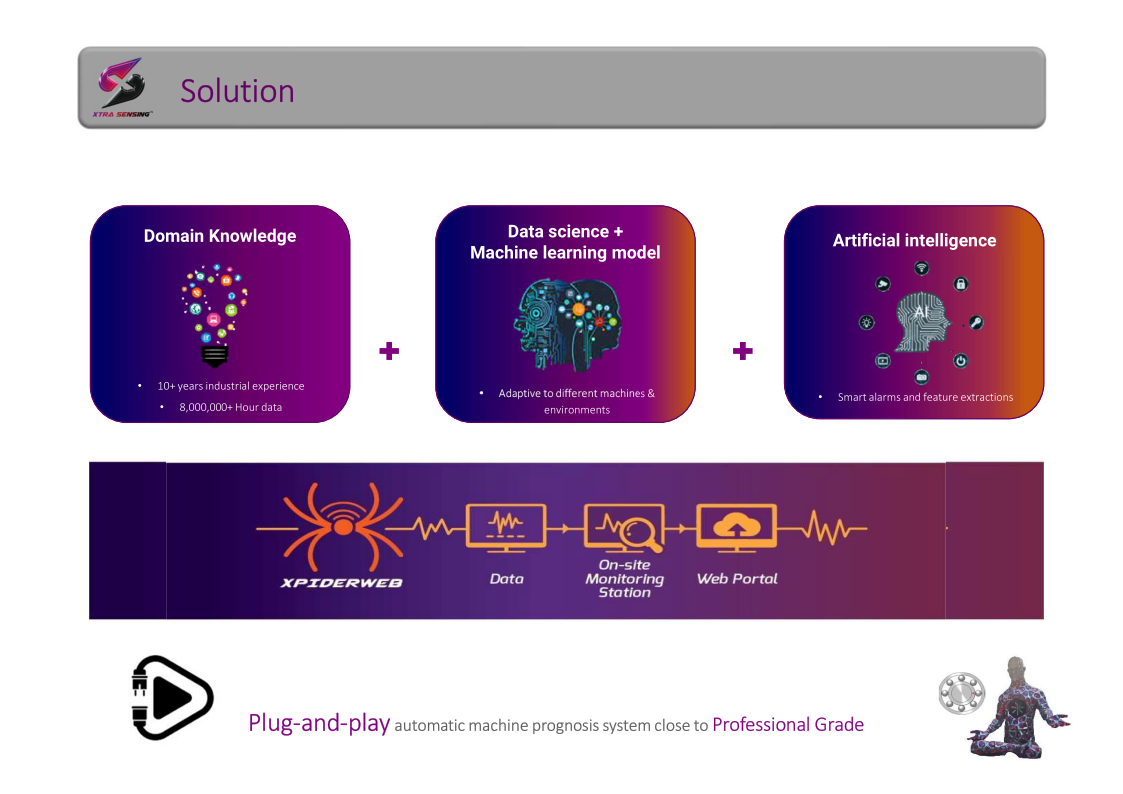

- Smart multi-channel triggering and high-sampling rate recoding ability to capture right data with Generative A.I. for post-data analysis & signal processing

- Innovative tiny Machine Learning technology for edge data processing

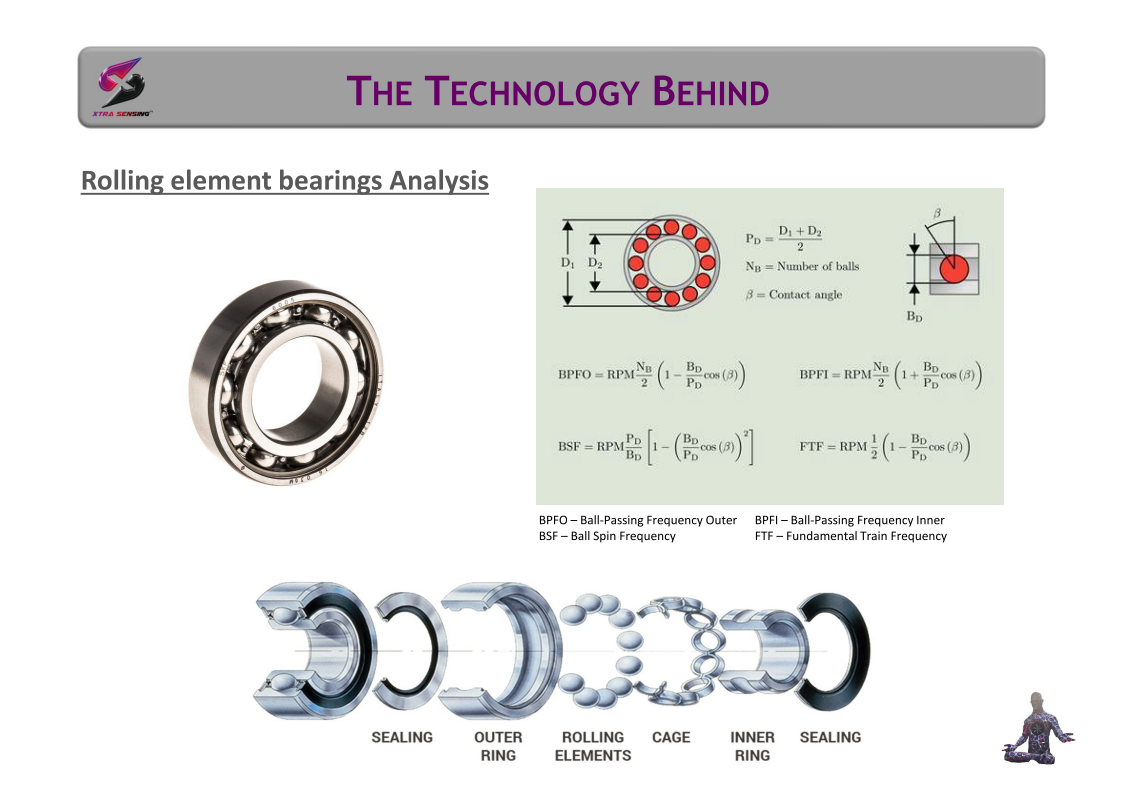

- Over 30,000 nos. of rolling element bearing fault frequency & symptom data pool

- Domain expert in Acoustics, Vibration & Machine Diagnostics, ISO Cat. III Certified Vibration Analyst & member of The Hong Long Institute of Acoustics (HKIOA)

|

| Trial Application and Expected Outcome |

- Collect data and provide insights on comparing the performance point machines under monitoring in terms of noise, vibration, motor current signature, temperature & relative humidity etc.

- Develop Machine Learning model to automate alarm triggering and determination of alarm threshold to save cost on routine visual & audible checking / inspection.

- Machine diagnostics on rotor balancing, misalignment, bearing fault, gear fault, motor coil & mechanical looseness.

- Integrate Generative A.I. & Tiny Machine Larning to traditional Non-Destructive Testing & Condition Monitoring techniques.

- Predict the next failure time of point machine and notify the operation team in advance to avoid sudden breakdown.

|

| Additional Solution Information |

I&T Soluion 2057 Attachment.pdf

|

| Info on I&T Solution Provider |

| Solution Provider | : | Xtra Sensing Limited | | Address | : | Unit 1017, 10/F, Building 19W, No. 19 Science Park West Avenue, Hong Kong Science Park, N.T., Hong Kong | | Contact Person | : | Andrew YEUNG |

| Position | : | CTO & Co-founder | | Tel | : | 2550 2330 | | Email | : |

andrew@xtrasensing.com | | Webpage | : | www.Xtrasensing.com |

|