| I&T Solution |

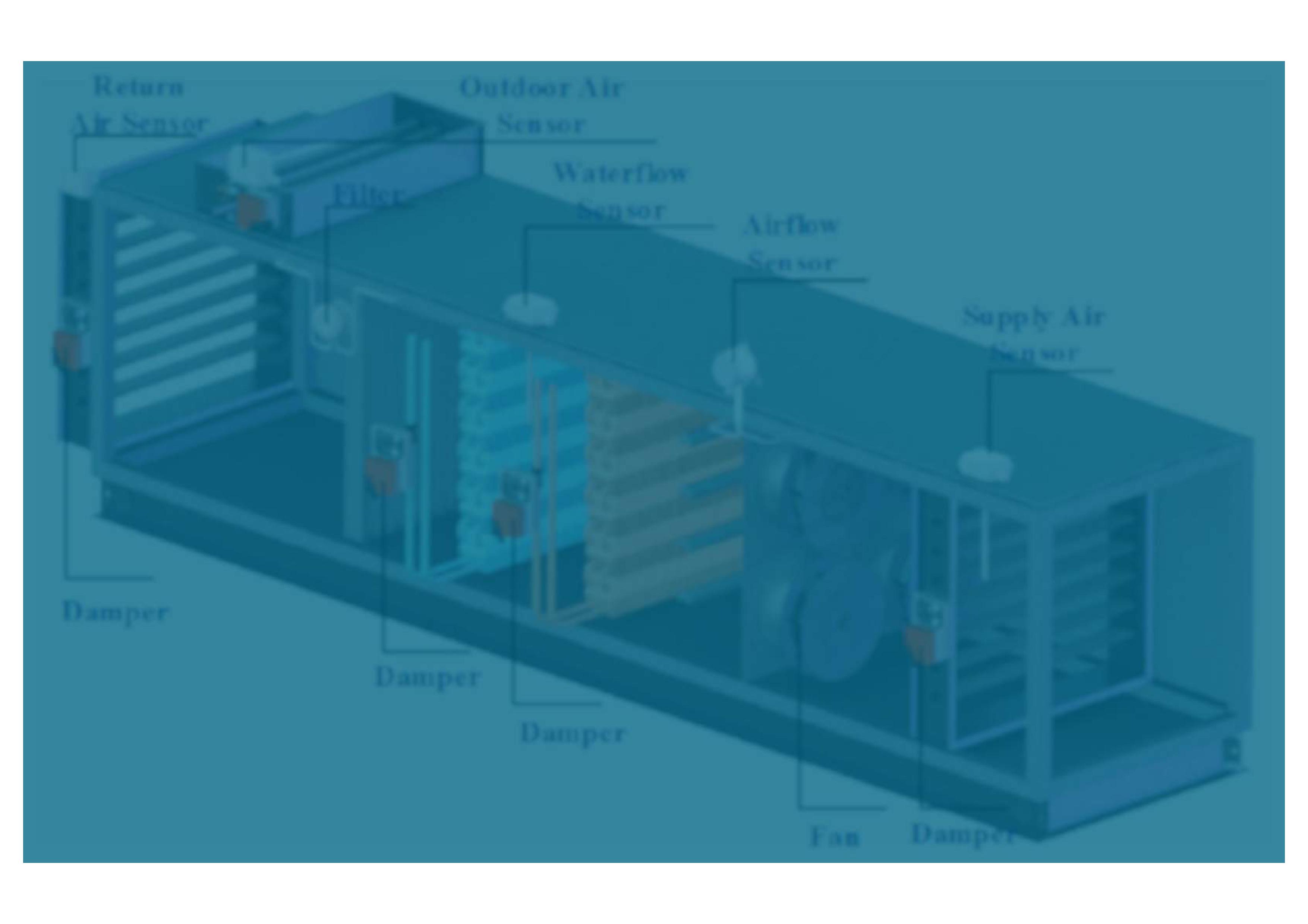

Artificial Intelligence (AI) Model for Predictive Maintenance of Air Handling Units (AHUs)

(REF: S-1630) |

| Trial Project |

|

| Solution Feature |

- Anomaly Detection: The AI model is capable of identifying anomalies in the operation of AHUs. This involves monitoring sensor data for abnormal values in parameters such as virbation, temperature, humidity, airflow, and pressure.

- Fault Prediction: The AI model can predict potential faults in AHUs, such as fan failures, issues in the transmission system, or sensor malfunctions. Early fault prediction allows for proactive maintenance, minimizing downtime and reducing the likelihood of costly repairs.

- Performance Optimization: Provide recommendations on how to optimize the performance of AHUs. This may include suggestions for adjusting fan speeds, replacing air filters, or optimizing setpoints based on historical data and current conditions. Continuous optimization suggestions contribute to improved energy efficiency, extended equipment lifespan, and reduced operational costs.

- Real-time Monitoring and Alerts: Implement real-time monitoring of AHU operations, allowing the AI model to promptly identify deviations from normal behavior. Generate real-time alerts to notify relevant personnel or maintenance teams about potential issues, enabling quick response and intervention.

- Data Analysis and Reporting: Conduct in-depth data analysis to provide insights into the AHU system's performance trends and patterns.

|

| Trial Application and Expected Outcome |

- Reduced Downtime and Unplanned Failures: The AI model's predictive capabilities enable early detection of potential issues and faults in AHUs. By addressing problems proactively, maintenance teams can perform necessary repairs or replacements before a major failure occurs, minimizing downtime and preventing unplanned disruptions to HVAC systems.

- Increased Equipment Lifespan: Proactive maintenance based on the AI model's predictions helps extend the lifespan of AHUs. Regular monitoring and timely interventions reduce wear and tear, preventing the equipment from experiencing severe damage and prolonging its overall operational life.

- Improved Energy Efficiency: The AI model can provide optimization recommendations for AHU operations. By adjusting parameters such as fan speeds, air filters, and setpoints based on real-time data and historical patterns, the system can operate more efficiently, leading to energy savings and reduced operational costs.

- Cost Savings on Maintenance: Predictive maintenance allows for planned and targeted interventions, avoiding emergency repairs and reducing the need for costly replacements. By optimizing maintenance schedules and resource allocation, organizations can realize significant cost savings over time.

- Enhanced Operational Visibility and Planning: The AI model generates comprehensive reports and insights into AHU performance. Maintenance teams and facility managers gain a deeper understanding of system behaviour, enabling better-informed decision-making. Organizations can plan maintenance activities more effectively, allocate resources efficiently, and make informed decisions about equipment upgrades or replacements.

|

| Additional Solution Information |

AI-AHUs.pptx

|

| Info on I&T Solution Provider |

|