| I&T Solution |

Guided-wave-based Smart Sensor for Inspecting the Integrity of Partially Buried Lamp Poles

(REF: S-1684) |

| Matched I&T Wish |

|

| Trial Project |

|

| Solution Feature |

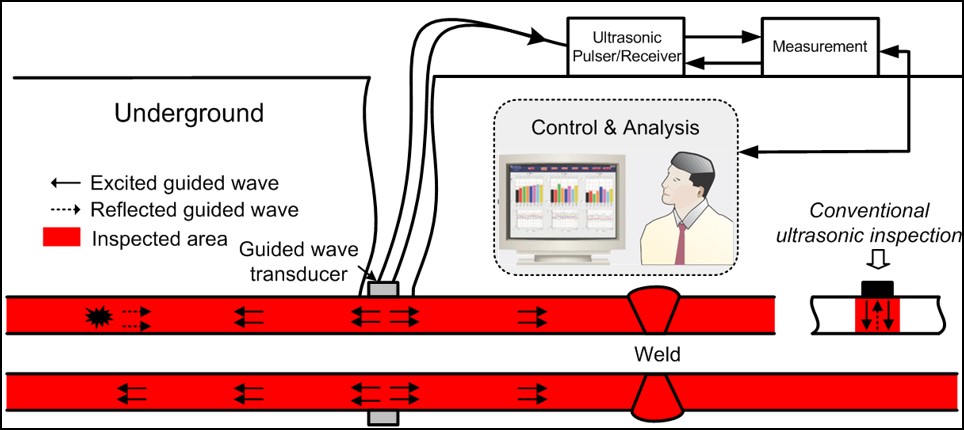

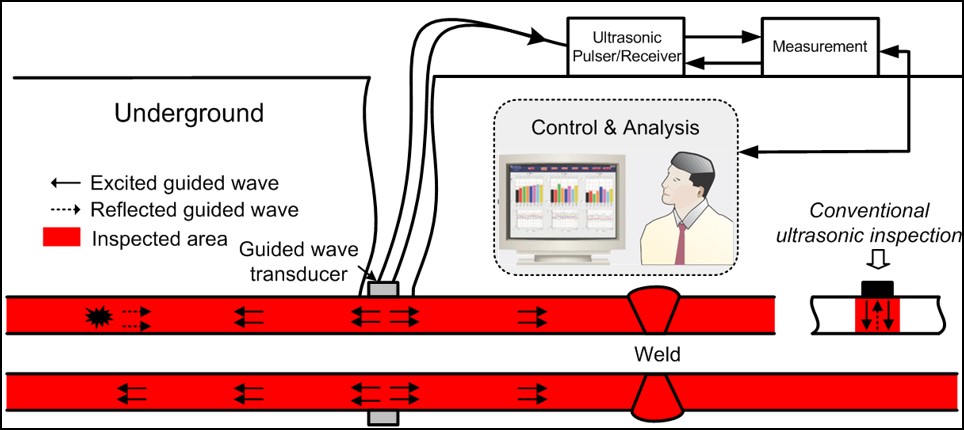

- The Guided-Wave-based (GW) system is an innovative technology that has been well-proven to be effective in determining the extent of defects and corrosion occur in partially buried pipes and ducts.

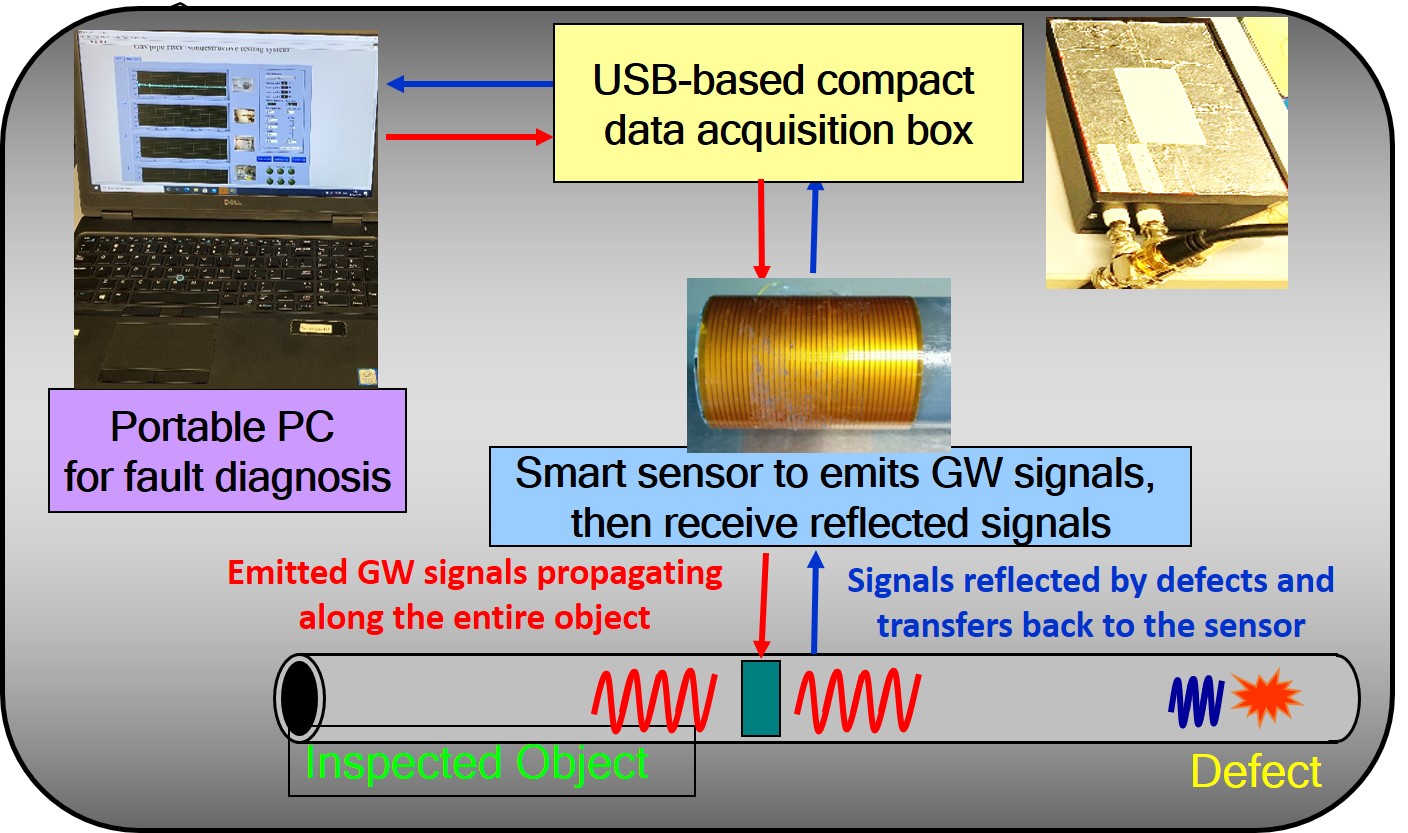

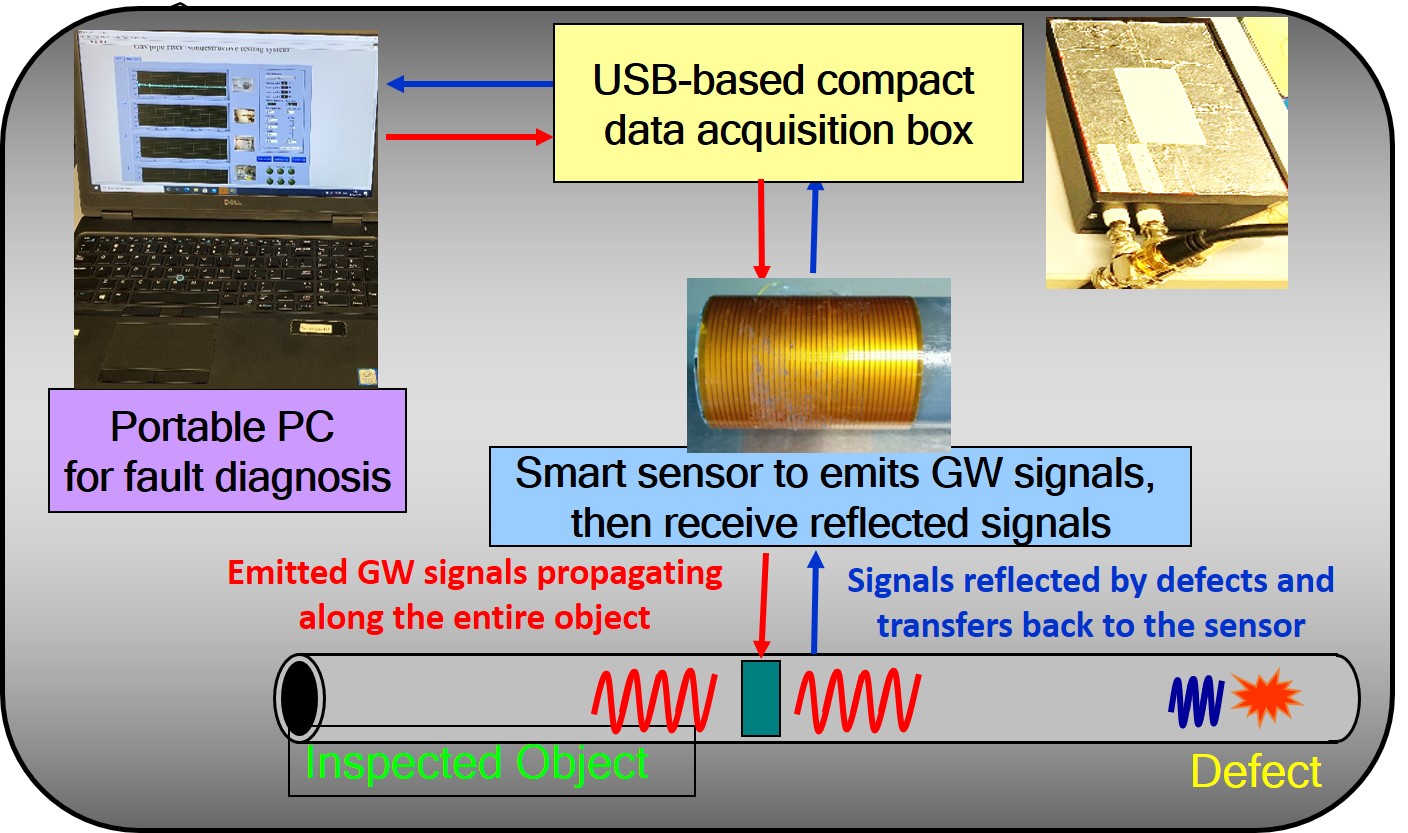

- The GW system consists of a laptop PC, a small USB-based data acquisition box and our innovatively designed smart sensors. It is portable and can be powered up via a USB plug or a battery pack.

- As of today, there is no commercial system can compete with our GW system based on the cost, ease-of-use and flexibility.

- The design of smart sensor is patented in US. It is thin and flexible with a smart material patch and our designed harmonized flexible printed coil (HFPC). It can be mounted on different sizes and shapes of poles. As of today, no commercial system can provide such compatibility.

- Not like other systems that their data cannot be extracted by users, the data collected by this system are opened to users for further analysis. In future, the collected maintenance data can be transferred to remote maintenance centre via Wi-Fi and performed AI-based proactive maintenance.

|

| Trial Application and Expected Outcome |

- Optimize the design of smart sensor. Enhance the efficiency in installing the smart sensor. The time and effort spent on mounting the sensor to the lamp pole will be minimized.

- Design a new pneumatic-based mechanism to tighten the surface contact between the smart sensor and the monitored pole. Expecting stronger GW energy will be emitted to the inspected pole.

- Different level of stress can be controlled by the new mechanism to suit the needs of applying the GW inspection system to different types and sizes of lamp poles.

- Manufacture the prototype of the optimized smart sensor. Experiments will be conducted to verify the capability and the operation efficiency of improved smart sensor.

- Draft the guidelines for producing the new smart sensor and mechanism. Search and recommend capable manufacturer(s) for future mass production of the optimized smart sensor.

|

| Additional Solution Information |

Additional Info - English-Chinese Aggregating Pneumatic Tightening Mechanism to Smart Sensor.pdf

|

| Info on I&T Solution Provider |

| Solution Provider | : | Ir Dr. Peter W. T. TSE and Ir Dr. Eric S. W. WONG | | Address | : | Room N105, 11/F, Valiant Industrial Centre, 2-12 Au Pui Wan Street, Fo Tan, Shatin, Hong Kong SAR, China | | Contact Person | : | Ir Dr. Peter W. T. TSE |

| Position | : | Consultant and Professor | | Tel | : | +852 92660207 or +1 672 8332208 | | Email | : |

peterptpt@yahoo.com.hk | | Webpage | : | https://www.seam-cndt.com |

|