| I&T Solution |

Development of robotic welding system and defect inspection devices for railings

(REF: S-0540) |

| Trial Project |

|

| Solution Feature |

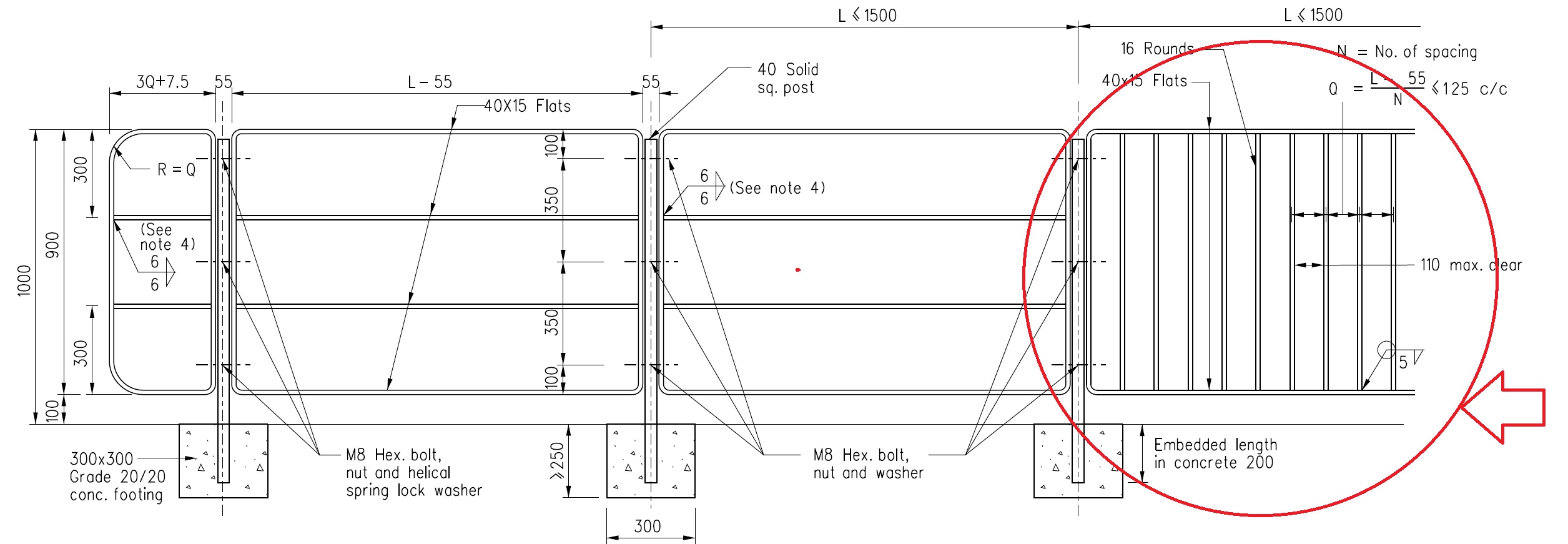

- The system is to handle the welding process of the round bars to the rectangle outer frame structure of the roadside steel railing. The overall system comprises of jig and fixture, rotational table, robotic welding arm, defect inspection system and safety guard.

- The loading and unloading of the workpiece will be conducted manually while the welding and inspection process will be conducted automatically.

- The jig and fixture is to provide a platform for labour to position the round bars and rectangle frame structure before welding process. The position of the workpiece will be controlled by means of pneumatic or electric devices in order to minimize the positioning time and error.

- The rotational table is to rotate the fixture and workpiece for allowing the robot to access both front and rear sides of the workpiece for minimizing the required accessible robot stroke. The robot can be fixed in a permanent base to ensure higher repeatability.

- The industrial grade 6-axis robotic arm installed with welding torch will be used for performing welding process. MIG welder and wire feeder will be equipped. Vision, ultrasonic waves or radiation beams type defect inspection system will be installed for evaluation of internal structure or external surface.

|

| Trial Application and Expected Outcome |

- The overall project will be divided into three phases – workflow and layout review, installation of automatic robotic welding system and defect inspection device.

- Phase 1: Workflow and layout review. To review the existing manual welding operation and propose review workflow and layout design to adopt automatic welding process.

- Phase 2: Automatic robotic welding system. To develop the detail specification of the robotic welding system and construct the design. To conduct FAT and modify design before shipment. To install the system and conduct safety review and UAT. To provide on-site operation training.

- Phase 3: Defect inspection device. To study and evaluate the on-site welding defect inspection methodology and propose appropriate approach (e.g. vision inspection, ultrasonic waves or radiation beams). To develop the detail specification, construct and install the inspection system. To conduct UAT and evaluate the effectiveness.

|

| Additional Solution Information |

Robotic welding System 20200317-2.pdf

|

| Info on I&T Solution Provider |

| Solution Provider | : | Hong Kong Productivity Council | | Address | : | HKPC Building, 78 Tat Chee Avenue, Kowloon, Hong Kong | | Contact Person | : | Samson SUEN |

| Position | : | Principal Consultant (Smart Manufacturing and Mainland Business Division) | | Tel | : | 2788 5552 | | Email | : |

samsons@hkpc.org |

|